Mike the Boilerman -

Gas Safe Registered boiler and central heating repair technician in west Berkshire

Mike the Boilerman -

Gas Safe Registered boiler and central heating repair technician in west Berkshire

The Ideal Icos is/was an advanced boiler for its time, but its a boiler with a very mixed reputation. It is one of the first successful condensing boiler designs where the manufacturer got it broadly right and was launched onto the market in 2003, in anticipation of the law changing to make condensing boilers mandatory. This change finally happened 2005.

The reasons for the mixed reputation are firstly the poorly designed and unreliable control board, with the control board failing in virtually every boiler sold within four or five of years of installation, and always out of warranty. This got the boiler off to a bad start but Ideal re-designed the board and the Version 9 (yes!) in the orange coloured case is broadly reliable.

The second reason is the frustratingly opaque error messages the boiler displays when it fails. The most common error code is alternating L and F. This is a ‘catch-all’ code meaning little more than “something went wrong”. The boiler has gone out and won’t re-light. Well yes we know that! The hard bit is working out why and the fault-tracing chart just gives a long list of possibilities to investigate, and from experience I know the list is not even definitive.

But getting down to some detail, this really common L/F fault code can be broken down into two types of error.

1) The boiler failed to light. The control system notices this and correctly turns the boiler OFF and displays the L/F error code.

2) The boiler lights correctly but a fault in the control system leads to it think the boiler did not light, even though in actual fact it did light, so the faulty control system incorrectly shuts the boiler down and displays L/F.

Most L/F errors fall into category 2 so the task is not to work out why it didn’t light (because it did), but to work out why the control system is failing to detect the combustion which is actually and genuinely present.

The following is a discussion of the possibilities, but isn’t exhaustive. There are so many possibilities that I’ve written this page as much as an aide memoire for myself as for site visitors.

The simplest and safest way to know if the boiler is lighting is to listen. An igniting boiler makes a noticeable if quiet, ‘whoomph’ noise as ignition occurs. If it goes to L/F without making the whoomph noise, then it didn’t light.

The first thing to check is the condensate drain. If its blocked, the boiler will run for a while then shut down showing L/F as the condensate level backs up and begins to interfere with combustion. Condensate drains are endless trouble. When run outside they can block with ice in cold weather, but even when connected entirely indoors to a nearby drain or waste connection they can block with sink fat, or worse.

Check there really is a gas supply present. Do other gas appliances in the house still work?

If it still won’t light, the chances are there is a component failure within the boiler. The favourite candidate is the gas control valve but before replacing it, check the thin plastic hose connection onto the gas valve is clear. If water or condensation gets into it or if the hose is kinked, this will affect the gas/air ratio and can easily prevent combustion.

This tells us the flame detection system is not working.

The flame detection electrode is a separate component from the ignition electrode. Its ceramic insulation can crack or if water has been poured through the heat exchanger during servicing to clean it and test the condensate drain, the electrode can be wet and cause the control board to fail to detect the flame. Replacing the electrode will rule these out.

The electrode needs to be correctly positioned. 25mm +/- 2mm from a straight edge laid across the top of the chamber.

The lead connecting the detection electrode runs directly agains the heat exchanger for about 8” and in the long tern the insulation tends to break down, leading to the wrong value of flame rectification current, which in turn makes the boiler decide there is no combustion even when there is, and L/F lockout results.

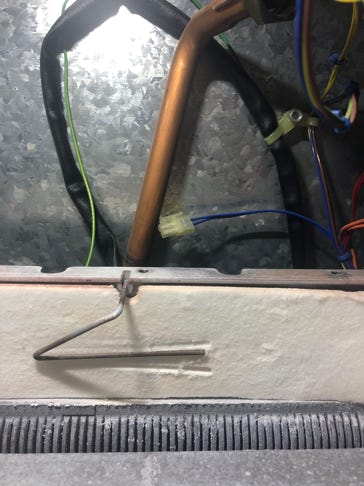

In addition to the flame detection electrode there are two “ionisation electrodes” inside the Icos heat exchanger and these are colloquially known as ‘coat hangers’, as the original design of electrode is reminiscent of a wire coat hanger in shape. I don’t fully understand what they do but they are important and Ideal have issued a formal Notice to replace them with a later, updated design at the first possible opportunity, usually the next service. I suspect this might be to do with nuisance L/F lockouts.

The flow pipe temperature sensor needs to be working. I’ve only just discovered this! I suspect the control board looks for a rising flow pipe temperature after ignition, to confirm the pump it working and there is a water circuit present. If the control board senses no rise in temperature, I think it shuts down combustion and displays L/F. So if the flow sensor has failed or is not correctly fitted onto the flow pipe, an L/F lockout will result.

Finally, there is the possibility of the gas injector being partially blocked with a spider web. Tiny spiders get into all manner of places in boilers and their webs can really mess up combustion and the gas jet in the Icos is prone to this apparently although I’ve yet to encounter it. I’ve experienced spider web contamination on one of my own gas appliances although not an Icos. The water heater in my boat started burning with a horrible yellow flame and I tracked it down to a tiny mesh of web threads spun inside the burner venturi. A good clean under a high pressure tap fixed it!

—————

Moving on from the L/F error, there are further issues with the Icos that lead to its ‘mixed’ reputation.

The condensate trap on a condensing boiler, especially on an aluminium heat exchanger boiler, collects debris and needs removal and cleaning during the annual service. On the Icos, the location of the condensate trap is awkward and access for removal and cleaning is poor even when there is plenty of room below the boiler. The installation manual says the boiler can be installed as close as 4” from a surface below which makes removal of the trap really difficult. Or more particularly, replacing it and making the pipe joint watertight near impossible. Consequently, service technicians under time pressure to service the boiler quickly tend to be reluctant to remove and clean the trap as re-fitting it with tight access can turn out to be very time consuming. So as you can perhaps imagine, cleaning it tends to get left out ‘just this time’. After a few years of leaving the trap uncleaned ‘just this once’, it fully blocks and the boiler stops working.

Ideal Icos condensing gas boiler.

(Image credit - Gumtree)

Inside the Ideal Icos combustion chamber, showing the ‘coat hanger’ style of ionisation electrode which must always be replaced

If you like what I write, please Buy me a coffee. Thank you kindly!

Copyright Michael Bryant 2025

Site first published 16th January 2004

Site last updated 13th November 2025

Gas Safe Register 197499, CIPHE registration number 009909L

This website makes use of cookies. Please see my privacy policy for details.